Automatic color grading

Beware the pitfalls in automatic color grading

A colour grading machine must be able to imitate the visual observation setup to produce results that accord with the human eye.

Automatic colour grading of diamonds is becoming increasingly important to the diamond business due to its ability to save time and bypass the possibility of human error.

However, systematic grading errors, due to the use of low-quality colour grading machines, have been reported. On the other hand, more sophisticated instruments, such as the Lumisense, yield consistently reliable results.

In recent years, the colour grading of diamonds has shifted increasingly towards automation. There are several diamond colour grading machines on the market, and they are used not only by individual diamond traders and diamond companies, but also by grading laboratories.

Machine colour grading

Lumisense, the new automatic diamond colour grading instrument used by HRD Antwerp Diamond Lab

However, reproducibility is not enough. It is relatively straightforward to build a machine that produces the same colour result over and over again. A more difficult requirement is that this result should not be in conflict with the opinion of experienced human observers. The human eye and the brain will always determine the ultimate standard, and a colour grading machine can only be successful if it is consistent with the processes taking place in our eyes and our brain during colour vision.

This also means that the illumination of the stone and the method of observation must be as close as possible to the procedures followed by human observers. For near colourless diamonds this includes: positioning the stone, table down, on a white background; illuminating it from above with a “northern daylight” (D65) light source, with the correct amount of UV included; observing the stone from several angles nearly perpendicular to the pavilion and to the girdle, and making an average of the different observations.

In many colour grading machines the stone is illuminated through the table. It is obvious that this is totally different from the visual method, and it will inevitably lead to systematic differences in the grading results. Moreover, just as for visual colour grading, colour grading machines must rely on calibration, based on internationally defined master stones.

Colour in diamonds

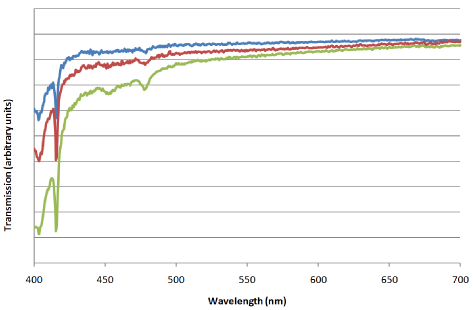

Fig 1. Transmission spectra in the visible range for three diamonds with a normal “Cape type” colour hue.

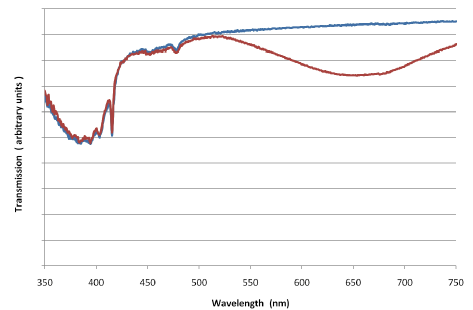

Fig 2. Schematic illustration of a problem with some less sophisticated colour grading machines, as explained in the text

Light is a wave phenomenon. Every wave can be characterized by its wavelength. Different wavelengths of visible light correspond to different colours of the rainbow. These wavelengths are extremely short compared to the dimensions we experience in everyday life. Visible wavelengths, violet to red, range from 400 to 700 nanometers (one nanometer is a millionth of a millimeter).

For every visible wavelength, we can measure the percentage of light transmitted by the stone. In this way, a transmission spectrum is obtained. This is illustrated in Fig. 1, for a number of stones, each having the typical colour hue for “normal” diamonds. As can be seen, all spectra here have essentially the same general shape. Transmission is lower in the blue-violet end of the visible spectrum (400-500 nm), and this is interpreted by our eyes and our brain as a yellowish colour.

For two such stones, the one with lower transmission will be considered as having a more intense colour. For a D-colour, the visible spectrum will closely approximate to a horizontal line near the top of the graph, for a fancy yellow the spectral transmission will be much lower, especially in the 400-500 nm region. Optical absorption in the visible spectrum of diamonds, and hence colour, is due to atomic scale defects in the crystal lattice.

Crystal imperfections as a cause of colour in diamonds

Diamonds with a generally reduced light output have a greyish appearance like this one

This diamond, however, does not have the greyish appearance and thus the light output is not reduced

The most common cause of colour in diamonds is the presence of aggregates of substitutional nitrogen atoms, replacing carbon in the crystal lattice. This leads to the typical “Cape-type” colour hue, of which the saturation may vary from extremely low – almost perfectly colourless – to very high – fancy intense yellow.

If the dominant impurity atom is boron, the stone may show a characteristic steely blue colour, such as for instance in the famous Blue Hope diamond. Diamonds of this type are extremely rare.

If a diamond is subjected to high energy radiation, carbon atoms can be removed from their position, and thus vacancies are created in the crystal lattice. These defects are at the origin of blue to green colours. Irradiation of diamonds can be carried out in a laboratory, but it can also happen in nature, when stones are in contact with radioactive minerals. In some cases, even the most sophisticated laboratory techniques are unable to bridge the difference between naturally and artificially irradiated diamonds.

Brown and pink colours are caused by different mechanisms, presumably plastic deformation of the crystal lattice. These defects have received a lot of attention in recent years, because in some diamonds it is possible to remove the associated colour by High Pressure High Temperature (HPHT) treatment.

A general lowering of the transmission of light, for example caused by a combination of blue and brown colour components, will lead to greyish colours.

Another important aspect is the shape of the stone. This is well known to diamond polishers who have their special methods for increasing, for fancy colours, or decreasing, for near colourless stones, the saturation of the colour. If the path length of the light in the stone is longer, the absorption will be higher, and the colour will be more intense. If the path length is shorter, the stone will be more colourless.

Automatic colour grading

This brings us to automatic colour grading that has been used successfully for many years. At the HRD Antwerp Diamond Lab, visual grading was supplemented by spectrophotometric measurements. However the number of stones that could be graded with this technology was seriously limited, because of diamond type, fluorescence and various other factors.In 2008, the Lumisense instrument was introduced, based on a totally new methodology. This advanced method replicates human observation very closely. The result is a remarkable improvement in the range, the reproducibility and the accuracy of colour grading that can be achieved. Moreover, Lumisense is not affected by the serious limitations (diamond type, fluorescence) mentioned above. The use of less sophisticated machines can easily lead to erroneous results, and this is well known in the trade. Errors can occur in machines that, at first sight, are quite satisfactory.

As mentioned, the human eye observes the complete visible spectrum. Information is collected from all wavelengths, and this information is used to determine the colour name. Certain commercial colour grading machines, however, do not measure the complete spectrum, but only limited wavelength ranges. This is illustrated schematically in Fig.2. If the colour grading machine only measures light from the violet-blue end of the spectrum (400-500 nm), the calculated colour grades may be satisfactory for normal, “Cape type” diamonds. For stones with a different spectral shape, however, this method may lead to problems. Fig. 2 shows two spectra which are widely different. The top spectrum is of the normal “Cape type”, the bottom spectrum leads to a greenish colour. In the blue-violet range, however, the spectra are nearly identical, and the machine will find identical colour grades.

Of course this problem doesn’t occur for top quality colour grading machines. Instruments such as Lumisense are able to distinguish between stones with a slightly different colour hue and will grade them accordingly.

Another problem may occur with greyish diamonds, stones containing defects that lead to a general lowering of the light output over the complete visible spectrum (as seen in the two images of diamonds on the left). Again, a sophisticated colour grading instrument will be able to identify stones with such less desirable characteristics.

It is clear that automated diamond colour grading can be extremely successful, not only for standard colours, but also for stones with slightly different hues. There is no doubt that in the future this will be extended to arbitrary shapes, and also to fancy colours. However, care should be taken with machines that do not accurately imitate the visual observation setup, or the processes taking place in the human eyes and brain during colour vision. They will inevitably lead to systematic errors.

Contact the authors

Everything you like to know about colour in diamonds...

Jef van Royen, HRD Antwerp – Research, Lier, Belgium

Everything you like to know about Lumisense...

Ivan Loots, WTOCD (Scientific and Technical Research Center for Diamond), Lier, Belgium.