Polish

Surface Morphology of Diamond (SUMODI)

Goal

The objective of this project is the automation of polish grading. Next

to the evaluation of polish lines also a range of other surface

defects needs to be detected. The final goal is a quantification

of the polish in an objective and standardized manner.

Description

The polish grading is done manually with the aid of a loupe 10x or

microscope. For the polisher the loupe is not the only aid to

evaluate polish lines during polishing. The

Avalon device visualizes the

polishing lines of a facet being polished. Both polishers and graders

can evaluate polish in a different way because of the different viewing conditions. This can lead to

inconsistency in the evaluation of the polish grade and

discussions between graders and polishers. Intelligent automation can

provide accurate and consistent information on the polish grade.

The nessecary equipment must be developed

for both polishers and graders.

Current status

The first part of the project concentrated on the nature of all the defects influencing the polish.

In

the picture on the left we see an image of polishing lines on a pavilion half. Heavy

polishing lines are clearly visible as a pattern of white stripes under

grazing light. The polish grade will depend on the visibility of the

polishing lines

In

the picture on the left we see an image of polishing lines on a pavilion half. Heavy

polishing lines are clearly visible as a pattern of white stripes under

grazing light. The polish grade will depend on the visibility of the

polishing lines The

next defect is extra facets. These appear by accident or to mask

remainders of the rough diamond. In both cases they lead to a downgrade

of the polish.

The

next defect is extra facets. These appear by accident or to mask

remainders of the rough diamond. In both cases they lead to a downgrade

of the polish. Burnmarks

have the look of faint oil stains on the facet. The visibility can

increase looking at the defect through the diamond from the opposite

side. The cause of burnmarks is oxidation of the surface due to

overheating the diamond during polishing.

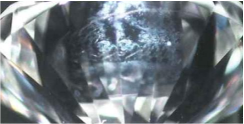

Burnmarks

have the look of faint oil stains on the facet. The visibility can

increase looking at the defect through the diamond from the opposite

side. The cause of burnmarks is oxidation of the surface due to

overheating the diamond during polishing. Fine

Scratches can lead to a downgrade of the polish grade. This depends on

the visibility. The grading rules state that the grading has to been

done looking at the diamond from the crown side with a loupe 10x.

Graders often tend to look through the pavilion side at scratches on the

table. This can lead to discussions between grading labs and polishers

about the correct polish grade.

Fine

Scratches can lead to a downgrade of the polish grade. This depends on

the visibility. The grading rules state that the grading has to been

done looking at the diamond from the crown side with a loupe 10x.

Graders often tend to look through the pavilion side at scratches on the

table. This can lead to discussions between grading labs and polishers

about the correct polish grade. Small

pits in the facet are judged by there visibility. Some common reasons for

pits are damages after polishing, left overs from rough, or break out of

micro crystals.

Small

pits in the facet are judged by there visibility. Some common reasons for

pits are damages after polishing, left overs from rough, or break out of

micro crystals.

There is a solution for visualizing polish lines, Avalon, but there is no measure for the visibility of these lines. This means that production time can increase, trying to remove details beyond visibility. The challenge of this project was to safeguard the quality but decrease production time per diamond.

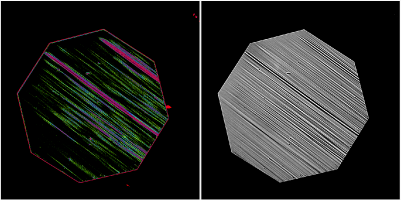

The first study tried to capture all classical parameters for surface roughness as being used in mechanical engineering. To measure the surface roughness we used a PSI device (Phase Shifting Interferometry) at VITO. The conclusion of this first test was disappointing, there was no link between human inspection and classical surface roughness parameters. Further investigations were focused on the mathematical relation between Avalon images and height data from the PSI. This finally leaded to a measure for the visibility of polishing lines calculated out of improved Avalon images. These results gave birth to a new device, AvalonPlus.

AvalonPlus, the ultimate Avalon

Compared to Avalon, AvalonPlus has:

- A sharper, high resolution, image

- Less internal reflections disturbing the image

- Build in dust avoiding measures

- A color coded evaluation of the visibility grade of polishing lines

- Extra facet measurements to improve production

- A sharper, high resolution, image

- Less internal reflections disturbing the image

- Build in dust avoiding measures

- A color coded evaluation of the visibility grade of polishing lines

- Extra facet measurements to improve production

No color = line invisible, green to red = slightly visible to clearly visible

At this moment the prototype of AvalonPlus is used to gather data in cooperation with the diamond industry. The aim is to create a standard polish grade combined with objective and consistent measurements used by industry and labs. Transparent, measurable, rules for polish are a benefit for the whole diamond sector and the consumer.

Contact

Everything you would like to know about Surface Morphology of Diamond

(SUMODI)...Dr. Peter ter Heerdt, WTOCD (Scientific and Technical Research Center for Diamond), Lier, Belgium.

Interested in a demo of AvalonPlus...

Erik Wanten, WTOCD (Scientific and Technical Research Center for Diamond), Lier, Belgium.