Processing

Advice on processing methods

Diamond polishing

As polishing is the most important processing step defining the quality of the cut of the diamond, and because

high quality is becoming more and more important, research on polishing principles and polishing techniques is

regarded the first step in optimising polishing for the new demands toward the industry.Vibrations in the polishing setup influence the surface quality of the facet, the wheel life and the risk of damage during polishing. WTOCD developed a low cost balancing set for ‘on the bench’ fine balancing of the polishing wheel after mounting. Changing friction properties and dynamic frictional behaviour (stick-slip) is another major cause of vibrations during polishing. Our research showed that higher surface quality and lower damage can be achieved at low constant friction.

Research is also performed in optimising the abrasive composition (grit size, size distribution, crystal shape, crystal friability) to optimise surface finishing (i.e. ‘zoeten’) at substantial production rates. A diamond paste for finishing with good frictional behaviour is being developed for cast iron ‘scaive’ usage. A water based polishing conditioner is available for increasing the surface finishing performance of the wheel.

Commercially available:

• balancing set

• finishing abrasive powder

• polishing conditioner

• finishing abrasive powder

• polishing conditioner

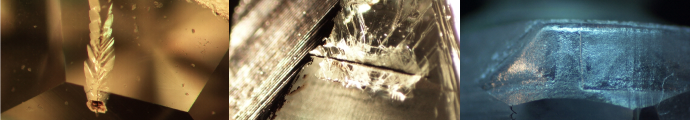

Stone damage

As our the Belgian industry's profile shifts towards larger and high-quality stones, the risk of damaging

the diamond during the subsequent processing steps become an increasingly important issue.Research is performed in mapping the damages. Manufacturers are encouraged to communicate damages, which have occurred during the processing of their stones. Main processing steps consist of laser working, bruting, polishing and abrasive sawing.

Damage risk when bruting stones has been made “extremely low” by our novel technology EOS. On demand, experiments can be carried out to pinpoint the processing parameters and determine their influence on the damage.

For all your questions on damaged diamonds during processing you can contact our technological advisor.

Contact

Ing. Guy Van Goethem