Reflex

Accurate proportion measurement

Goal

The objective of this project is to improve the accuracy of measurement of

the proportions and symmetry of polished diamonds.

Description

The commercially available systems for measuring the proportions of polished stones all use a

projection of the profile (shadow method) to scan the diamond. The diamond is rotated between

a telecentric light source and a telecentric lens. The contour of the shadow of the diamond is

then analyzed in a computer to determine its proportions.

This method has some typical disadvantages concerning accuracy.

The ultimate objective of this project was to build a system with much higher accuracy than the

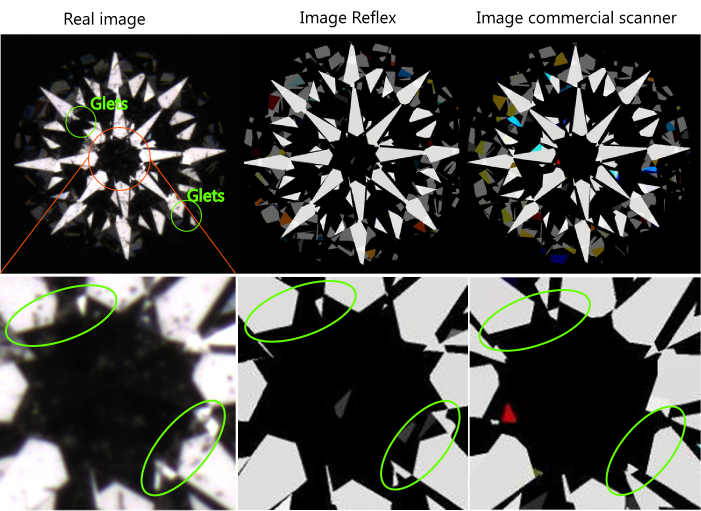

existing systems by using other methods different from the shadow method.To illustrate the accuracy we use a real life example in combination with the HRD Antwerp H&A viewer. This perfectly aligned equipment together with the directional light setup is ideal to compare commercial scanners and Reflex. The data extracted from the measurement is used to build the 3D-model. These models are visualized with the DiamCalc software from Octonus. So we have the real image, seen trough the HRD Antwerp H&A viewer, and the virtual image of the measured diamond, seen in a virtual environment based on the parameters of the H&A viewer. The creation of H&A patterns is extremely sensitive to angle variations, and , by nature, very useful as a tool to visualize slight differences in measurements. Let's start with the arrow side:

The real image shows two incomplete arrows. This is caused by an

internal defectin the crystal lattice, called a glets. This is not

visible in the simulated images because they are based on the external

characteristics only. The center of the images is enlarged to visualize

the differences between the measurements. It is clear that the model

build with Reflex data is far more accurate than the one build from the

data of the commercial scanner. The heart side reveals following pictures:

The real image shows two incomplete arrows. This is caused by an

internal defectin the crystal lattice, called a glets. This is not

visible in the simulated images because they are based on the external

characteristics only. The center of the images is enlarged to visualize

the differences between the measurements. It is clear that the model

build with Reflex data is far more accurate than the one build from the

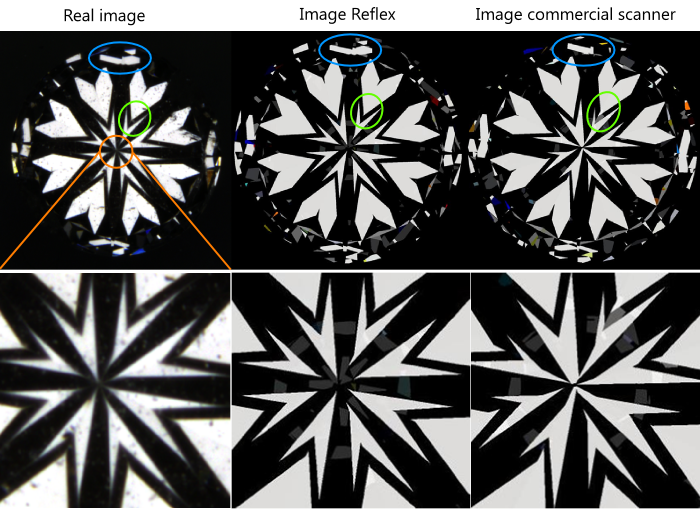

data of the commercial scanner. The heart side reveals following pictures: The blue and green markers

show some differences in the hart and surrounding patterns. The middle

is enlarged to show the importance of a high accuracy measurement.

The blue and green markers

show some differences in the hart and surrounding patterns. The middle

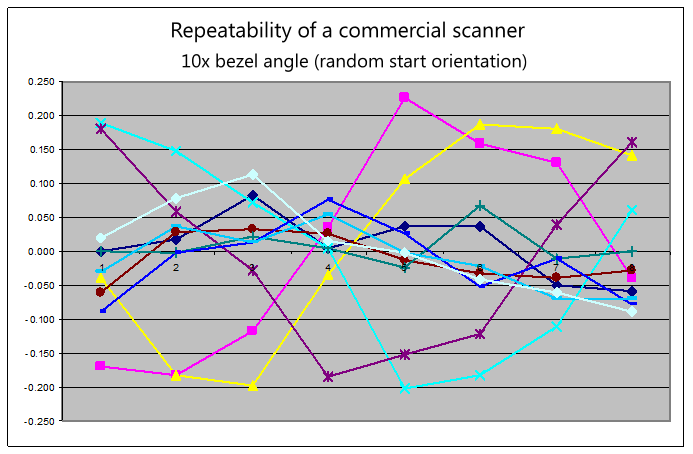

is enlarged to show the importance of a high accuracy measurement.To test the repeatability we measured the angles of 8 facets of a brilliant 10 times. Between each measurement we removed the diamond and put it back in a random position. The commercial scanner gave following results:

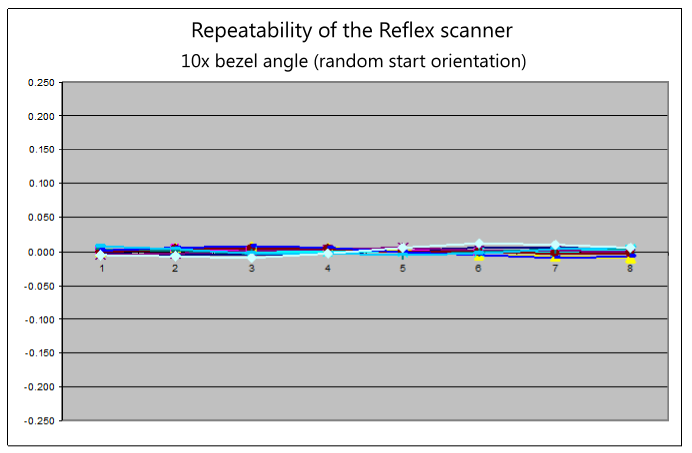

The results for the Reflex prototype are shown in the next picture:

For less time critical applications like calibration the device is already suitable. Also the possibility for a future as "proportions referee" is now being investigated.

Current status

Experiments have shown that higher accuracies are possible. Angles (both inclination and index) can be measured with accuracies up to ±0.02º.

The distances can be measured with submicron accuracy. A prototype is being evaluated.