EOS

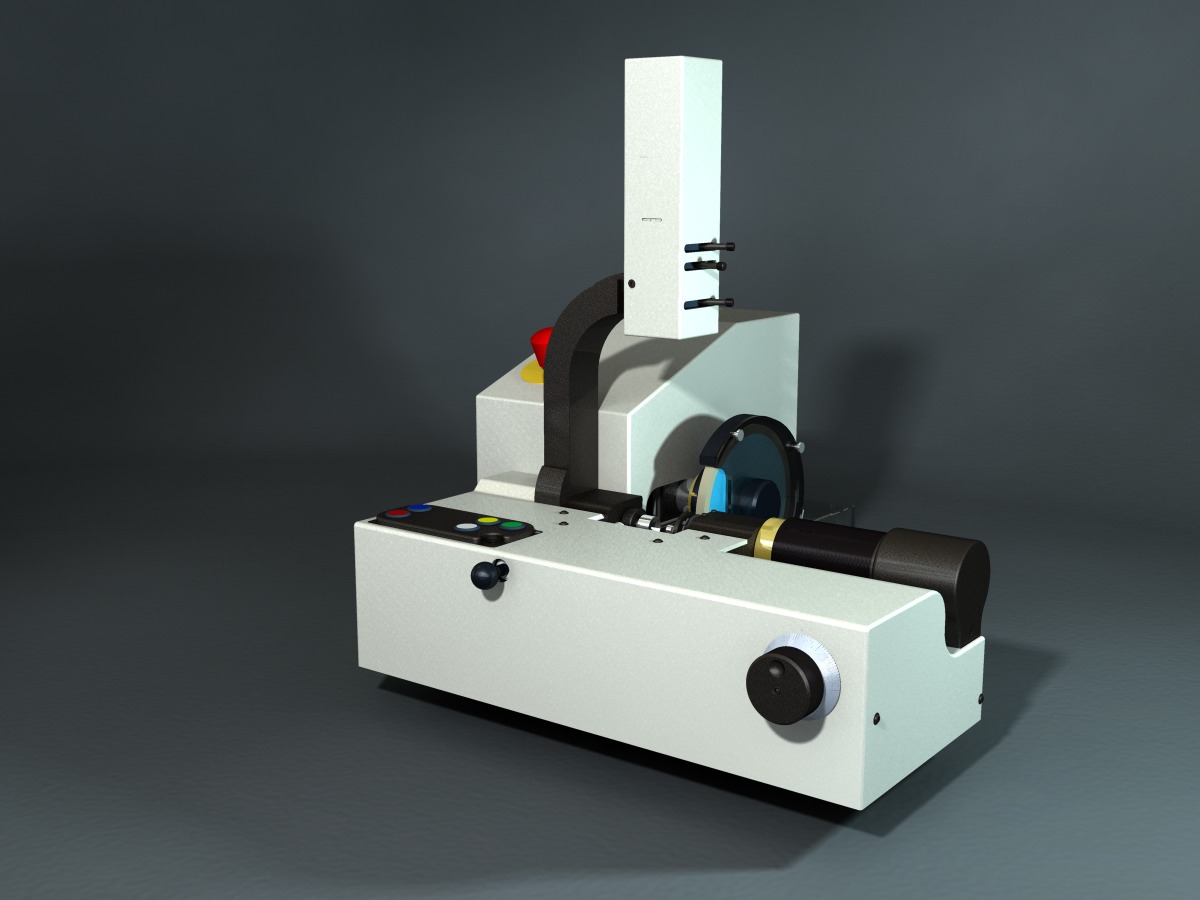

Ultimate bruting machine

Purpose

Development of a high quality, high yield bruting machine for all types of diamond goods.

Description

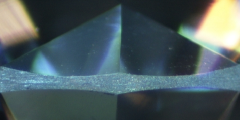

BrutingIn former days, bruting was mainly performed in a process with loose abrasive grit, originating from rubbing diamonds against each other or against a diamond tool, as to present sharp cutting edges. However this frequently leads to fractures (“beard” and “gletses”) and chipping at the edges of the working surface. Working diamond with fixed abrasive grit has been limited to polishing in the soft crystal direction. As the abrasive is firmly bonded in the tool, it tends to become blunt. Working in the hard crystal direction shows a substantial, up til 100 times, lower Material Removal Rate (MRR).

ELID

In an ELID (Electrolytic In Process Dressing) system the bonding of the abrasive is weakened by an electro-chemical reaction, to loosen the blunt grit and to create new sharp grit at the surface of the grinding wheel. This technology is also applied in Russian make bruting machines for gem diamond.

Our research showed that ELID is difficult to tune if the workpiece properties are changing frequently (as is the case for mono-crystalline natural diamond). For this reason the electrochemical action is set high to prevent working in a blunt regime. This leads to a low G-ratio and is therefore only economically applicable with low cost grinding wheels. Moreover the electrolysis is not constant and has to be tuned in time to cope with the influences of temperature and changing chemical composition of the electrolyte. Pre-dressing and wheel re-shaping is needed for optimum performance and quality in diamond processing.

EOS-process

WTOCD developed a new bruting principle whereby processing is accomplished in a constant optimal working condition without the

use of electrolysis and its disadvantages. A careful selection of the grinding wheel properties, machine parameters and grinding

principles enables us to work all type of diamond with high quality at high removal rates. The grinding wheel stays sharp and

flat during its entire life without any need for out of process dressing or tuning. This condition is inherent to the setup and

therefore is guaranteed by the application.

WTOCD developed a new bruting principle whereby processing is accomplished in a constant optimal working condition without the

use of electrolysis and its disadvantages. A careful selection of the grinding wheel properties, machine parameters and grinding

principles enables us to work all type of diamond with high quality at high removal rates. The grinding wheel stays sharp and

flat during its entire life without any need for out of process dressing or tuning. This condition is inherent to the setup and

therefore is guaranteed by the application.

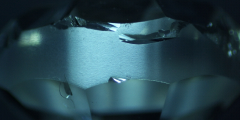

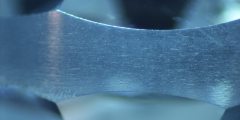

Bruting features

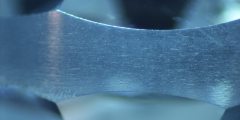

- Girdle roundness typically better than 15 μm

- Perpendicularity girdle/table better than 0,1

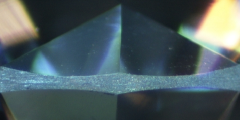

- ‘Beardless’ girdle. Goods incorporating micro-fractures can be processed without propagating the fractures

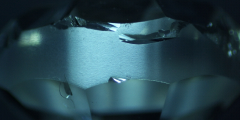

- Smooth surface, no grooves or polishing tracks. Slightly satin visual impression

- Bruting without facet edge chipping. Ideal for repair work.

- Stones with high stress, even in the bruting area, can be processed without any damage.

- Fractures (gletses) already in the rough do not chip off and do not propagate into the stone.

- No damage to the stone.

- Girdle roundness typically better than 15 μm

- Perpendicularity girdle/table better than 0,1

- ‘Beardless’ girdle. Goods incorporating micro-fractures can be processed without propagating the fractures

- Smooth surface, no grooves or polishing tracks. Slightly satin visual impression

- Bruting without facet edge chipping. Ideal for repair work.

- Stones with high stress, even in the bruting area, can be processed without any damage.

- Fractures (gletses) already in the rough do not chip off and do not propagate into the stone.

- No damage to the stone.

Examples of EOS-bruting

EOS Demo video

EOS Demo video

This movie shows all the aspects of this bruting machine. Besides the

principles also the handling of the diamond and the machine are

illustrated.

This movie shows all the aspects of this bruting machine. Besides the

principles also the handling of the diamond and the machine are

illustrated.

EOS Demo video

EOS Demo video This movie shows all the aspects of this bruting machine. Besides the

principles also the handling of the diamond and the machine are

illustrated.

This movie shows all the aspects of this bruting machine. Besides the

principles also the handling of the diamond and the machine are

illustrated. Contact

For Commercial applications:, website Comdiam

For experimental applications and advice: