D-Screen

Identification of synthetic and HPHT treated

diamonds

Purpose

This appliance quickly and reliably identifies diamonds that are neither synthetic nor HPHT colour enhanced from batches of cut

colourless or nearly colourless diamonds (colour D to J).

Description

Diamond sector threatened by synthetic and treated stones.

Up until the sixties, a colourless or nearly colourless diamond was by definition a natural stone. The eighties saw the first synthetic ornamental diamonds appearing on the market made using HPHT synthesis (HPHT = High Pressure High Temperature).

In 1999, the first reports of commercial HPHT treatment started to appear. This process gained a great deal of attention, as the technique could turn some brown diamonds into colourless ones. It was, after all, the very first technique for ‘removing’ colour.

In 2001, the American firm Apollo Diamond announced its plans to produce synthetic diamonds using CVD techniques (Chemical Vapour Deposition). It also became known that it was possible to change the brownish colour of some CVD diamonds to colourless using the HPHT treatment.

The arrival of these new techniques heralded an enormous challenge for scientists and researchers. They embarked upon an intensive search for new techniques to identify the nature of a diamond: natural, treated or synthetic. These techniques were also preferably to be user-friendly, reliable and economical.

After years of research, the ‘D-Screen’ has been developed to bolster confidence in diamonds.

The D-Screen is a practical research device developed by WTOCD and HRD Research. It distinguishes stones that are not synthetic and have not been HPHT colour enhanced from stones that are potentially synthetic or may have had their colour improved by means of HPHT.

The D-Screen is a practical research device developed by WTOCD and HRD Research. It distinguishes stones that are not synthetic and have not been HPHT colour enhanced from stones that are potentially synthetic or may have had their colour improved by means of HPHT.

Is your diamond NATURAL, SYNTHETIC and/or ENHANCED to have a ‘perfect’ colour?

What you must know about colour

Types of diamond

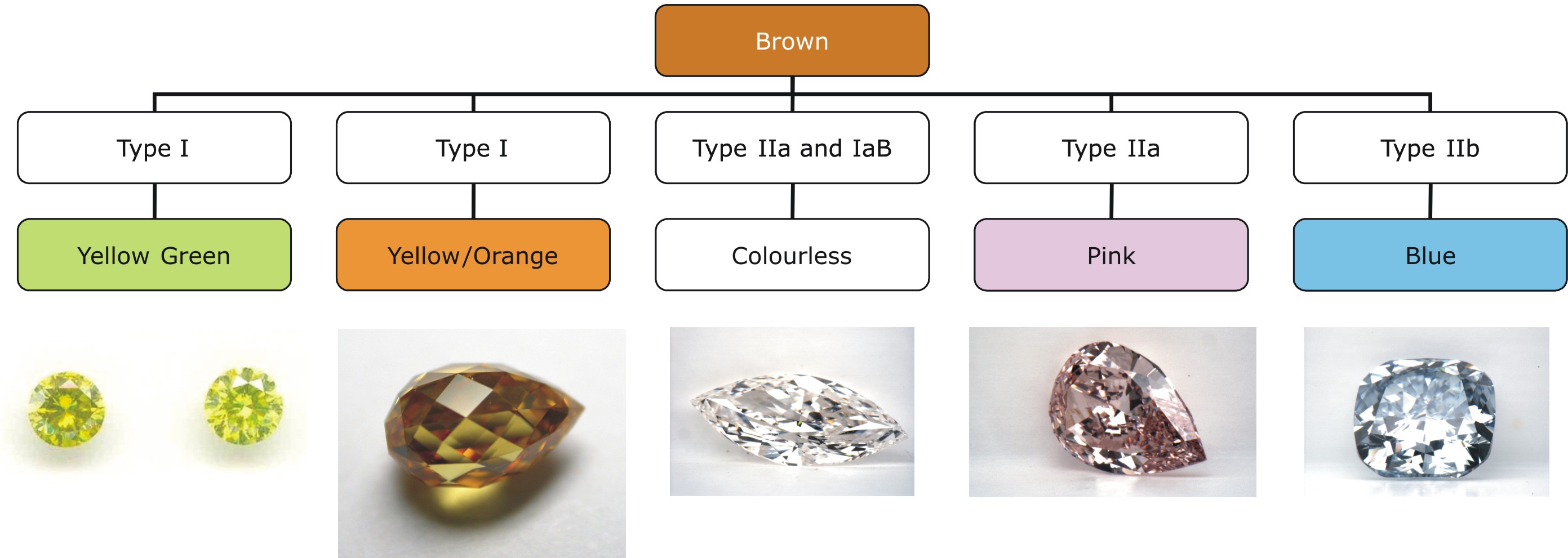

A diamond with a perfect crystal lattice made entirely of carbon would be completely colourless. In reality, however, all diamond crystals contain atomic impurities and structural defects. We call these defects colour centres because they are responsible for the colour of a diamond.

The most common atomic impurity in a diamond is nitrogen. Based on the presence of this atom in the diamond lattice, one can classify diamonds into two main groups.

Type I diamonds contain a higher level of nitrogen, while type II diamonds contain practically no nitrogen.

Type I diamonds

Type I diamonds account for the large majority of cut diamonds (bigger than 98%). The nitrogen atoms present can be grouped (type Ia) or isolated (type Ib). Because some of these nitrogen groups absorb blue light, type Ia diamonds often have a light yellow colour that can vary to brownish yellow or brown. Diamonds with isolated nitrogen atoms (type Ib) usually have a deep yellow to orange colour.

Natural type Ib diamonds are very rare, accounting for less than 0.1% of the total quantity of natural diamonds of precious stone quality. After their formation, most diamonds remain in the upper part of the earth’s mantle for millions of years under high pressure and subject to high temperatures. In this environment, the nitrogen atoms gradually group to become aggregates, so the diamonds change from type Ib to type Ia. Synthetic diamonds are, however, always very young so they usually contain a very high relative level of isolated nitrogen.

Type II diamonds

Type II diamonds contain very negligible levels of nitrogen. Because nitrogen is generally the most prominent impurity, this type can be considered the atomically purest form of diamond. One can also distinguish two subgroups here; these are type IIa and type IIb. The first group is very pure and can be completely colourless. These stones do, however, often contain structural defects that can give them a brown to pink colour.

Type IIa diamonds are very rare in precious stone quality (approximately 1% to 2% of all diamonds), and the most famous colourless diamonds such as the Cullinan and the Koh-I-Noor are of this type.

Type IIb diamonds (less than 0.1% of all diamonds) have substitute boron atoms in the crystal lattice. As a result, these diamonds are blue, although they can also be brown and grey to nearly colourless. All natural blue diamonds are type IIb, so also the famous/infamous Blue Hope diamond.

What you must know about treatmentsWhat you must know about colour

Types of diamond

A diamond with a perfect crystal lattice made entirely of carbon would be completely colourless. In reality, however, all diamond crystals contain atomic impurities and structural defects. We call these defects colour centres because they are responsible for the colour of a diamond.

The most common atomic impurity in a diamond is nitrogen. Based on the presence of this atom in the diamond lattice, one can classify diamonds into two main groups.

Type I diamonds contain a higher level of nitrogen, while type II diamonds contain practically no nitrogen.

Type I diamonds

Type I diamonds account for the large majority of cut diamonds (bigger than 98%). The nitrogen atoms present can be grouped (type Ia) or isolated (type Ib). Because some of these nitrogen groups absorb blue light, type Ia diamonds often have a light yellow colour that can vary to brownish yellow or brown. Diamonds with isolated nitrogen atoms (type Ib) usually have a deep yellow to orange colour.

Natural type Ib diamonds are very rare, accounting for less than 0.1% of the total quantity of natural diamonds of precious stone quality. After their formation, most diamonds remain in the upper part of the earth’s mantle for millions of years under high pressure and subject to high temperatures. In this environment, the nitrogen atoms gradually group to become aggregates, so the diamonds change from type Ib to type Ia. Synthetic diamonds are, however, always very young so they usually contain a very high relative level of isolated nitrogen.

Type II diamonds

Type II diamonds contain very negligible levels of nitrogen. Because nitrogen is generally the most prominent impurity, this type can be considered the atomically purest form of diamond. One can also distinguish two subgroups here; these are type IIa and type IIb. The first group is very pure and can be completely colourless. These stones do, however, often contain structural defects that can give them a brown to pink colour.

Type IIa diamonds are very rare in precious stone quality (approximately 1% to 2% of all diamonds), and the most famous colourless diamonds such as the Cullinan and the Koh-I-Noor are of this type.

Type IIb diamonds (less than 0.1% of all diamonds) have substitute boron atoms in the crystal lattice. As a result, these diamonds are blue, although they can also be brown and grey to nearly colourless. All natural blue diamonds are type IIb, so also the famous/infamous Blue Hope diamond.

HPHT colour treatment

General Electric (GE) developed the high pressure (HP) - high temperature (HT) treatment in the mid-nineties with the purpose of

changing the colour of ‘lower quality’ (read: light brown) diamonds.

With this treatment, the stone is heated to temperatures of over 2100°C. To prevent the diamond from being transformed into graphite,

this takes place at a very high, stabilising pressure.

General Electric (GE) developed the high pressure (HP) - high temperature (HT) treatment in the mid-nineties with the purpose of

changing the colour of ‘lower quality’ (read: light brown) diamonds.

With this treatment, the stone is heated to temperatures of over 2100°C. To prevent the diamond from being transformed into graphite,

this takes place at a very high, stabilising pressure.

The brown colour in some types of diamond (incl. type IIa) is associated with the presence of plastic deformation or defects in the crystal lattice. HPHT treatment changes these defects in the crystal lattice and the cause of the colour disappears.

The whole process often takes only a few minutes, but the diamond must then be cut to remove the mat, corroded surface to have it sparkle again.

The final result of this treatment greatly depends on the initial properties and the type of the treated diamond. Today, starting with a brown, grey or light yellow diamond, one can achieve a whole range of colours going from intense yellow, to greenish yellow to pink and blue and colourless.

HPHT synthesis

The purpose of this technique is to synthetically produce a diamond by replicating the formation conditions of diamonds deep in the earth. By applying a high pressure (HP) and high temperature (HT) to a carbon source, one “forges” a synthetic diamond. The first such stone was produced in 1953 by Swedish researchers at the ASEA, soon followed by General Electric and De Beers. Since the seventies, one has thus been able to produce diamonds of precious stone quality that today are sold for approx 30% of the price of a natural diamond.

By keeping the conditions stable for a longer time, one can ‘grow’ a rough diamond of 2 to 3 carat in just a few days.

The majority of these stones are coloured bright yellow to orange due to the presence of nitrogen atoms in the crystal lattice. They are type Ib diamonds. It is also possible to grow colourless (read: nitrogen-free) diamonds, but the technical problems involved remain sizeable and such stones are practically absent from the diamond market.

CVD synthesis

Chemical Vapour Deposition is the process through which diamond is produced from a (carbonaceous) gas. The principle was already known in the nineteen thirties, but it took until the start of this century before one succeeded in growing larger single diamond crystals instead of polycrystalline material.

The gas (methane is usually used) is heated to a very high temperature. Atom compounds are then broken down, after which the carbon atoms can ‘precipitate’ onto a surface. Under the right conditions, a single crystal is formed that becomes thicker layer by layer. A typical speed for a good quality diamond is half a millimetre a day.

CVD diamonds are - because of technological problems - usually light brown in colour, making them relatively unattractive to the average diamond trader. However, HPHT treatment often makes it possible to remove the brown colour. Immediately colourless diamonds are also expected to become available in the future.

D-Screen, compact, reliable and fast!

You must first check that the stone is a diamond, cut (one facet is sufficient), colour D to J, and with a weight between 0.20 and 10 carats.

You place the diamond to be examined with the table downwards on the detector. Close the unit and after a few seconds one of the indicators comes on and you can read off the result:

- green indicator: the stone is not synthetic and not HPHT colour enhanced.

- orange indicator: the stone may be synthetic or HPHT colour enhanced, the stone requires further examination in a laboratory.

- red indicator: low battery voltage or defective unit

D-Screen characteristics

- compact size: 4 x 5 x 15 cm

- use: battery or AC (including cable)

- weight: 325 g, including battery

- power: 9 V DC, 250 mA

- adaptor input: 110-230 V 50/60 Hz

- adaptor output: 9 V DC, 300 mA

The advantages of D-Screen:

- simple check to see if your stones are not synthetic or HPHT colour enhanced using current technologies

- fast and correct result br />- compact and user-friendly

- ergonomic

- mobile use (battery)

- price/quality

- all diamond cut forms are suitable

- screening of +/- 200 stones/hour

- simple check to see if your stones are not synthetic or HPHT colour enhanced using current technologies

- fast and correct result br />- compact and user-friendly

- ergonomic

- mobile use (battery)

- price/quality

- all diamond cut forms are suitable

- screening of +/- 200 stones/hour

Contact

For Commercial applications:, website Comdiam

For experimental applications and advice: