Hearts and Arrows

Cutting Hearts and Arrows, the quest

for ultimate quality ...

Creating Hearts and Arrows (H&A) is not a trivial task. It is very important that polishers know the relationship between the proportions and the H&A patterns.

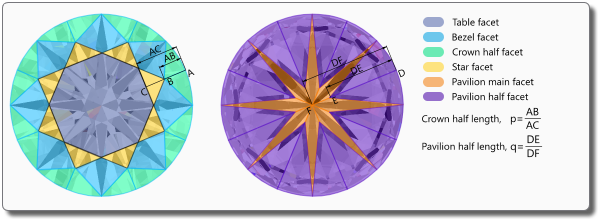

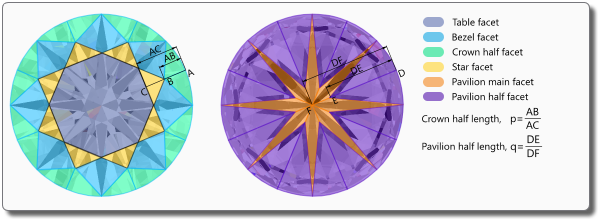

From all brilliant parameters the following are crucial in the process of creating H&A:

- The table facet

- The star facet

- The crown angle (bezel)

- The crown half length (p)

- The pavilion main facet angle

- The pavilion half length (q)

To make a H&A by HRD Antwerp brilliant, only certain combinations of parameters are allowed. Besides the right cut parameters a highly symmetrical cut is necessary for an H&A

by HRD Antwerp. To avoid misunderstanding, the assumption is made that every brilliant in this article has a perfect symmetry. Let’s take a look at the

relation between these parameters and H&A. The pavilion angle is the most important parameter in the processing of H&A brilliants. If the pavilion main

facet angle is out of range then creating H&A by HRD Antwerp is impossible. The lower–half facets determine the pavilion half length (q). This parameter is

crucial in the process of creating the heart shapes. The only parameter left affecting the heart shapes is the table. If the hearts are formed, only a small

range of crown angles will lead to clearly visible arrows. To facilitate the making of H&A by HRD Antwerp, the right crown angle ranges for each combination

of pavilion angle and table size should be used. In the next section, the effect of variation on each cut parameter is discussed.

To make a H&A by HRD Antwerp brilliant, only certain combinations of parameters are allowed. Besides the right cut parameters a highly symmetrical cut is necessary for an H&A

by HRD Antwerp. To avoid misunderstanding, the assumption is made that every brilliant in this article has a perfect symmetry. Let’s take a look at the

relation between these parameters and H&A. The pavilion angle is the most important parameter in the processing of H&A brilliants. If the pavilion main

facet angle is out of range then creating H&A by HRD Antwerp is impossible. The lower–half facets determine the pavilion half length (q). This parameter is

crucial in the process of creating the heart shapes. The only parameter left affecting the heart shapes is the table. If the hearts are formed, only a small

range of crown angles will lead to clearly visible arrows. To facilitate the making of H&A by HRD Antwerp, the right crown angle ranges for each combination

of pavilion angle and table size should be used. In the next section, the effect of variation on each cut parameter is discussed.

The common parameters are:

Variation in the pavilion half length influences the gap between the v-shaped arrow head and the heart shape. Lowering the pavilion half length (<74%) gradually removes the gap between the heart and the V.On the arrow side the arrows get wider. Increasing the half length (>79%) makes the gap between the V’s and the hearts wider and creates incisions in the heart shapes. The arrows become thinner. It should be noticed that the range of acceptable half lengths is very narrow. In the next animation the variation on the heart pattern is illustrated with pavilion half lengths ranging from 72% to 82%. The color scheme illustrates the "H&A by HRDAntwerp" grade for arrows.

The common parameters are:

The table size and the crown angle

The table size effects the shoulder width of the hearts. The line formed at the crossing of the table and the star facets results in a flattened heart shape if the

table is smaller than or equal to 60%. Tables bigger then 60% give pointed shoulders and are rejected as H&A by HRD Antwerp. The crown angle is very important for

the creation of the arrows. In the following animation we see the evolution of the arrows as a function of the crown angle and a

fixed pavilion (main pavilion facets and lower-half facets). The background color of the crown angle field illustrates the H&A by HRD Antwerp grading. If the background color is

red, the arrows are

rejected. An orange background points to a

border case.

A green background gets an arrow grade with

zero penalty (in case of perfect symmetry).

The common parameters are:

The crown half length has an impact on “clustering”. Clustering means that the arrow shafts are surrounded with white areas. Only a limited amount of clustering

is allowed. The clustering is accompanied by another effect around the arrowheads. This effect is an exaggeration of the small triangular facets aside

the arrowheads. It is caused by a combination of pavilion angle, pavilion half length and crown half length. When the pavilion main facet angle increases

above 41° the chances on clustering are higher. In combination with half lengths below 45% (star length of 55%) and pavilion half length above 77% clustering

is unavoidable. The left picture gives an example of excessive clustering. Small non disturbing clusters result in a penalty but excessive clustering and side effects

leads to rejection.

The crown half length has an impact on “clustering”. Clustering means that the arrow shafts are surrounded with white areas. Only a limited amount of clustering

is allowed. The clustering is accompanied by another effect around the arrowheads. This effect is an exaggeration of the small triangular facets aside

the arrowheads. It is caused by a combination of pavilion angle, pavilion half length and crown half length. When the pavilion main facet angle increases

above 41° the chances on clustering are higher. In combination with half lengths below 45% (star length of 55%) and pavilion half length above 77% clustering

is unavoidable. The left picture gives an example of excessive clustering. Small non disturbing clusters result in a penalty but excessive clustering and side effects

leads to rejection.

- For a pavilion angle smaller than 40.6°, the crown half length is between 45 and 50%

- For a pavilion angle between 40.6° and 41.0°, the crown half length is 50 to 55%

- For a pavilion angle greater than 41.0°, the crown half length is between 55 and 60%

- Girdle thickness is 2.5 to 4%

- Culet is pointed

- Weight is between 0.5 and 3 ct

- Perfect symmetry

Choose the desired table width, pavilion angle

and pavilion half

length.

The correct bezel angle interval and the angle for the lower-half facet

angle is calculated. The background

color indicates the possibility to receive the H&A by HRD

Antwerp grade. Notice the very sharp change in half

length for a small variation in angle.

The half length varies 1% for a 0.04° difference in the lower-half facet angle. It is obvious that this is the

most critical point in polishing H&A by HRD Antwerp. The crown half length is adjusted to avoid the clustering-effect as described in the previous section.

A printable version of the full article you can find here

All images created with the aid of DiamCalc Pro from Octonus.

- The table facet

- The star facet

- The crown angle (bezel)

- The crown half length (p)

- The pavilion main facet angle

- The pavilion half length (q)

The Pavilion angle and half length

To get H&A, a pavilion angle between 40.0° and 41.8° is

necessary. For producing H&A by HRDAntwerp the range of 40.5° to

41.0° is more realistic. All other angles give heavy side

effects on the arrow shapes. At the border the arrows appear

colored or completely disappear. In the next animation the

images show the evolution of the Arrow patterns for pavilion angles between 40.00° and 41.80°.

The corresponding heart image is normal and approved by the

Hearts grading of "H&A by HRDAntwerp". If the background color is

red, the arrows are

rejected. An orange background points to a

border case.

A green background gets an arrow grade with

zero penalty (in case of perfect symmetry).

The common parameters are:

| Parameter | Value |

| Crown angle | 35.00° |

| Table size | 57.00% |

| Crown half length | 50.00% |

| Pavilion half length | 77.00% |

| Girdle height | 2.70% |

Variation in the pavilion half length influences the gap between the v-shaped arrow head and the heart shape. Lowering the pavilion half length (<74%) gradually removes the gap between the heart and the V.On the arrow side the arrows get wider. Increasing the half length (>79%) makes the gap between the V’s and the hearts wider and creates incisions in the heart shapes. The arrows become thinner. It should be noticed that the range of acceptable half lengths is very narrow. In the next animation the variation on the heart pattern is illustrated with pavilion half lengths ranging from 72% to 82%. The color scheme illustrates the "H&A by HRDAntwerp" grade for arrows.

The common parameters are:

| Parameter | Value |

| Crown angle | 35.00° |

| Table size | 57.00% |

| Crown half length | 50.00% |

| Pavilion angle | 40.70° |

| Girdle height | 2.70% |

The table size and the crown angle

The common parameters are:

| Parameter | Value |

| Pavilion angle | 40.70° |

| Table size | 57% |

| Crown half length | 55% |

| Pavilion half length | 76% |

| Girdle height | 2.70% |

The crown half length

The crown half length has an impact on “clustering”. Clustering means that the arrow shafts are surrounded with white areas. Only a limited amount of clustering

is allowed. The clustering is accompanied by another effect around the arrowheads. This effect is an exaggeration of the small triangular facets aside

the arrowheads. It is caused by a combination of pavilion angle, pavilion half length and crown half length. When the pavilion main facet angle increases

above 41° the chances on clustering are higher. In combination with half lengths below 45% (star length of 55%) and pavilion half length above 77% clustering

is unavoidable. The left picture gives an example of excessive clustering. Small non disturbing clusters result in a penalty but excessive clustering and side effects

leads to rejection.

The crown half length has an impact on “clustering”. Clustering means that the arrow shafts are surrounded with white areas. Only a limited amount of clustering

is allowed. The clustering is accompanied by another effect around the arrowheads. This effect is an exaggeration of the small triangular facets aside

the arrowheads. It is caused by a combination of pavilion angle, pavilion half length and crown half length. When the pavilion main facet angle increases

above 41° the chances on clustering are higher. In combination with half lengths below 45% (star length of 55%) and pavilion half length above 77% clustering

is unavoidable. The left picture gives an example of excessive clustering. Small non disturbing clusters result in a penalty but excessive clustering and side effects

leads to rejection.

Choosing the proportions for "H&A by HRD Antwerp"

After polishing the pavilion main facets, the pavilion lower-half facets and the crown main facets (bezels) need to be polished.

The bezel angle range in combination with the desired table width is

calculated with the H&A by HRD Antwerp calculator.

The following assumptions were made :

- For a pavilion angle smaller than 40.6°, the crown half length is between 45 and 50%

- For a pavilion angle between 40.6° and 41.0°, the crown half length is 50 to 55%

- For a pavilion angle greater than 41.0°, the crown half length is between 55 and 60%

- Girdle thickness is 2.5 to 4%

- Culet is pointed

- Weight is between 0.5 and 3 ct

- Perfect symmetry

Conclusion

This page provides the necessary information needed to produce an H&A by HRD Antwerp. The availability of the right parameters makes the polishing process for

H&A easier than before. Still, only ultimately skilled polishers can deliver the perfect symmetry with the right proportions.A printable version of the full article you can find here

All images created with the aid of DiamCalc Pro from Octonus.